Environment

Reducing consumption

At BIRN , we want to show responsibility by minimising our negative impact on the environment. We are therefore working proactively to reduce our energy consumption and increase our recycling of natural resources and surplus heat, and we are investigating how we can contribute positively to our surroundings.

As a result of energy-intensive processes at high temperatures and large consumption of raw materials, the world’s iron and steel production accounts for a large share of global emissions of greenhouse gases. As one of the largest foundry groups in Northern Europe, and thus an emitter of greenhouse gases, we are committed to continuing our work to reduce emissions connected with our operations and to share our results with stakeholders.

BIRN Group

Sustainability Report 2024

For the third year in a row, we are publishing a sustainability report for the entire BIRN Group.

Download the Sustainability Report

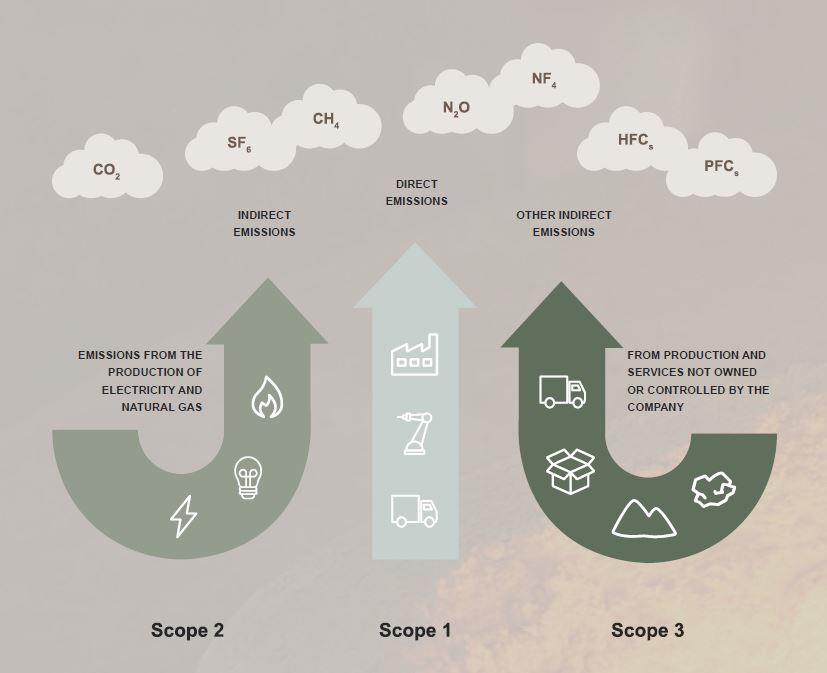

Mapping of carbon emissons

BIRN has spent much of 2024 producing the double materiality analysis. The analysis gives us a 360-degree view of the entire group in relation to the impact we have on the outside world, and how external factors impact us as a group. It’s a powerful starting point for defining concrete goals for how we can minimise our negative impact on the climate and environment, and identifying focus areas that are beyond our own control but which we need to take into account in our business operations.

In relation to the climate and environment, it is particularly BIRNs consumption of electricity, natural gas and resources and our production waste that have a significant impact on our surroundings, making these also the key areas to work with to minimise negative impacts.

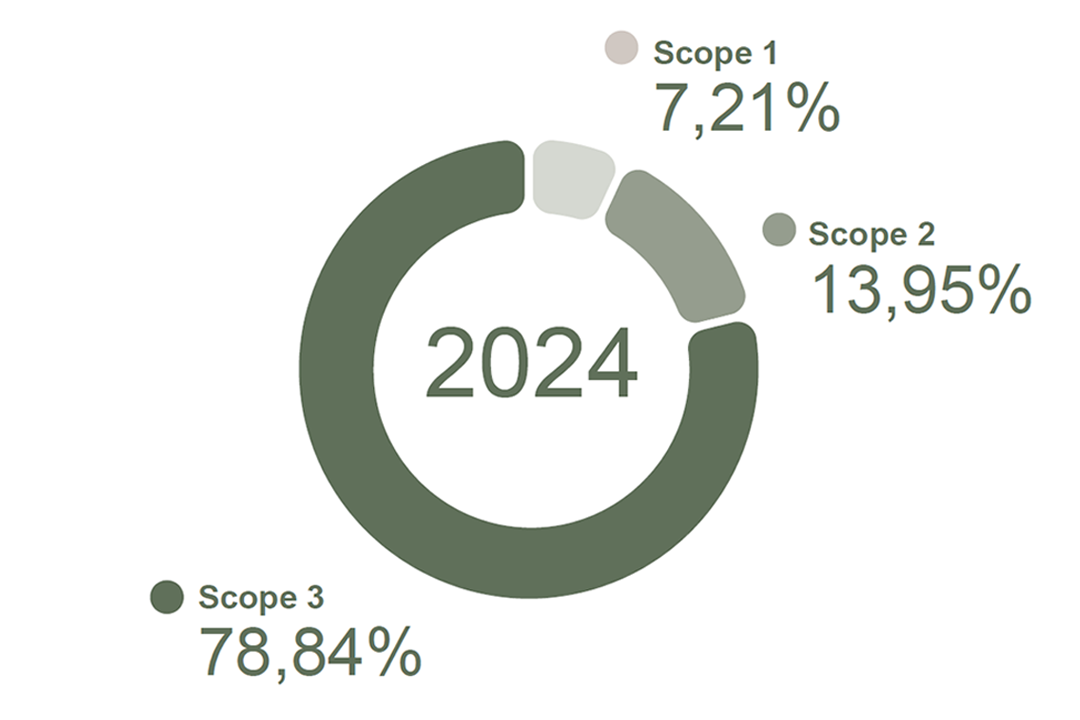

CO2 equivalent emissions

The chart shows the percentage distribution of CO2 equivalent emissions from BIRN in Holstebro in 2024.

Energy consumption

Electricity consumption is rising throughout society, and one way to cater to the increased demand is to improve the balance between demand and production. This applies in particular to the power we use for melting, holding furnaces, casting and the machining of cast iron.

Power reduction in the melter without loss of production

In collaboration with Fellowmind, Inuatek and University of Southern Denmark, BIRN has initiated a large-scale project on collection of energy and process data from melting furnaces, machinery and other production equipment. The purpose is to acquire better data insight, which can lead to decisions that can significantly minimise energy consumption and climate footprint.

Melting furnaces to help improve energy efficiency

BIRN has recently completed an AI-project in cooperation with pour-tech AB to optimize dosing of molten iron from casting machines into molds. The project aims to reduce energy consumption and has been such a success that BIRN is now planning to scale the technology to almost all the foundry's pouring units.

BIRN tests power regulation in pilot project

BIRN has entered a partnership with IBM and Energi Danmark to regulate our foundry’s electricity consumption. The collaboration will initially consist of a pilot project to relieve the grid and thus ensure a better balance.

Natural gas consumption

BIRN Group has a goal of using no natural gas, in line with our customers’ expectations. Therefore, we have made investments in alternative forms of energy, and have a strong focus on increasing the share of renewable energy in our energy mix

Natural gas phase-out well underway

BIRN Group has a goal of using no natural gas, in line with our customers’ expectations. This means that natural gas will eventually no longer be used for domestic hot water and heating offices, or for process heating in production.

Surface treatment plant markedly reduces natural gas consumption

Since 2021 BIRN has been treating components in a new surface treatment centre where new technology makes it possible to coat castings with a water-based ED paint, rather than the solvent-based paints used previously.

BIRN reduces natural gas consumption by 25% using heat recovery

BIRN aims to reduce its natural gas consumption by around 25 per cent by 2024. The reason is the recirculation from two new heat recovery plants that utilize the excess heat from parts of BIRN's production to heat the rest of the company.

Circular business model

Circular mindset

The BIRN Group’s business model is based on a circular economy mindset. For us, it has long been common sense to consider how we use and consume the planet’s resources.

Read moreSustainability

ESG - Environment, Social and Governance

BIRN Group expects to be covered by the new EU Corporate Sustainability Reporting Directive (CSRD) from the 2027 financial year.

However, we are already documenting and mapping how we work with sustainability throughout the group.

Contact

Sustainability is an important driver in ensuring the future success of our business. Do you want to know how we work with sustainability?

Emil Husted Brodersen, Group Sustainability Manager

Let's talk