Power reduction in the melter

Power reduction at the furnaces without loss of producition

Electricity consumption is rising throughout society, and one way to cater to the increased demand is to improve the balance between demand and production. Regulating power, whereby electricity consumption and production can be adjusted, plays a major role In this context. It is based on the fact that large consumers, such as industrial and production companies, are able to reduce their power needs and thereby help to better balance the electricity grid.

BIRN in Holstebro joined the Flex Platform in 2024. This is a technological solution developed by IBM and Andel Energi that signals electrical installations in real-time to adjust power consumption during periods when the grid is under high load. This allows power to be diverted from BIRN when it is needed in the rest of the grid, without affecting production at BIRN.

About Flex Platform

Flex Platform is a Danish technological solution created in a partnership between Andel Energi and IBM Danmark. The solution is based on artificial intelligence (AI) and the Internet of Things (IoT), and is designed to support the green transition through intelligent predictions and more flexible energy consumption. A number of both private and public sector participants are connected to the platform.

This automated regulation relieves coal and gas-fired backup power plants, which otherwise supply power in situations where stable and high energy supply is necessary for production capacity and quality – i.e. when there is peak demand for power on the electricity grid. Companies like BIRN in Holstebro thereby contribute to reducing the use of fossil fuels and lowering carbon emissions.

The iron foundry also helps increase the security of electricity supply for neighbours and other companies in and around Holstebro, by offsetting some of the renewable energy shortfall in the electricity grid that Denmark’s focus on green power may lead to.

Flexible consumption with no impacts

The electricity regulation collaboration was put to the test at BIRN in Holstebro in 2024. Adjustments to power consumption have been activated in the iron foundry’s melting furnaces several times, and according to Emil Husted Brodersen, Group Sustainability Manager at BIRN Group, this has not impacted production:

“Our initial experiences with power regulation have been 12-30 minutes on average. None of the reductions in electricity consumption have had an impact on production. We can always disable the system manually if we really need to, but this has not been necessary so far.”

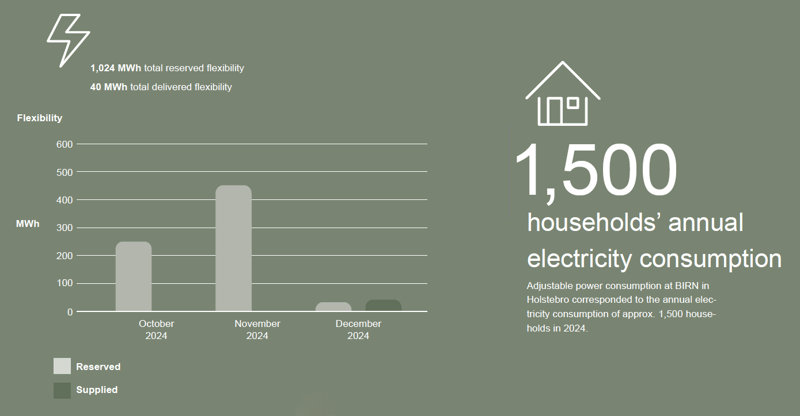

Even the relatively few adjustments that have been activated so far at BIRN in Holstebro have contributed positively to the overall energy balance. The amount of power that has been reserved at BIRN as regulating power corresponds to the annual consumption of about 1,500 households.

“We want to support the stability of the grid, so it makes sense to contribute in this way, where we can reduce our power usage during periods when it has no impact on production. We therefore look forward to being able to contribute even more in the coming years,” says Emil Husted Brodersen.

Three of the foundry’s melting furnaces are connected to the Flex Platform. This continuously collects data that is processed and analysed using artificial intelligence. The platform makes it possible to accurately predict electricity consumption and adjust it at times when the available renewable energy can be optimally utilised without compromising the operation of the melting furnaces.